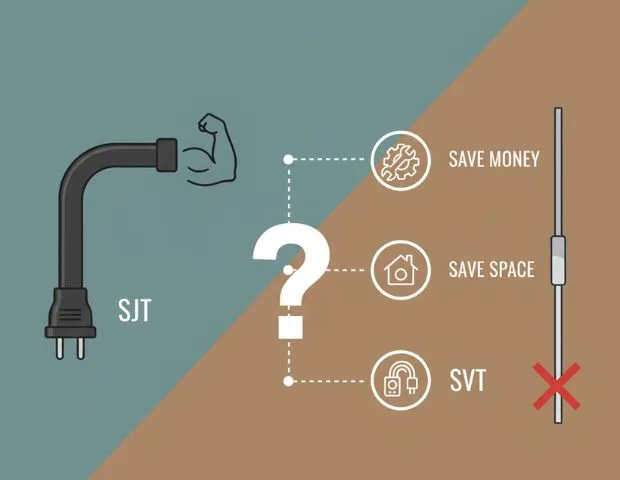

SJT vs. SVT Power Cords: Which Is Better for Heavy-Duty Use?

-

High Tech Connections > Blog > Power Cords > SJT vs. SVT Power Cords: Which Is Better for Heavy-Duty Use?

Key Takeaways:-

- SJT cords are more rugged and suitable for heavy-duty industrial and outdoor use.

- SVT cords are lighter and ideal for light-duty, indoor applications.

- SJT cords support higher voltage and amp ratings than SVT cords.

- Durability, insulation, and safety certifications make SJT cords a better long-term investment.

- SVT cords are budget-friendly but may require more frequent replacement.

- FAQs

When it comes to choosing the right power cord for demanding electrical applications, there are a lot of considerations to keep in mind. Durability, flexibility, safety, and compliance all come into play, especially when working in environments that require reliable power delivery. Two common types of cords you’ll hear about are SJT power cords and SVT cords. They may look similar at first glance, but when it comes to performance in heavy-duty settings, the differences can be crucial.

What Are SJT and SVT Power Cords?

Before diving into the comparison, it’s important to understand what these cords are and what their labels stand for.

SJT stands for “Service Junior Thermoplastic.” These cords are typically rated for 300 volts and are insulated with thermoplastic materials. They are known for being tough, flexible, and resistant to oils and chemicals. This makes them highly suitable for a wide range of applications in both residential and industrial settings.

On the other hand, SVT stands for “Service Vacuum Thermoplastic.” Like SJT cords, SVT cords are also made with thermoplastic insulation, but they are generally lighter and less robust. SVT cords are commonly found in applications where high durability is not the top priority, such as in small appliances or light-duty power equipment.

Voltage and Ampacity Ratings

One of the key differences between SJT and SVT cords lies in their voltage and ampacity ratings. SJT power cords are typically rated for higher amperage and voltage levels, usually around 10 to 15 amps and up to 300 volts. This makes them ideal for power tools, industrial equipment, and outdoor applications where performance and reliability matter.

In contrast, SVT cords generally support a lower current, usually up to 10 amps. They are best suited for indoor use and for devices that don’t draw a lot of power. So if you’re dealing with machinery or equipment that requires a substantial and steady power supply, SVT may not be the ideal choice.

Durability in Harsh Environments

Another factor that distinguishes these cords is their ability to withstand environmental stress. SJT power cords are designed to be more durable. They can handle abrasion, impact, and exposure to harsh chemicals and oils. That’s why you’ll often find them in factories, workshops, and construction sites. They can also endure rough handling and are more resistant to wear and tear over time.

SVT cords, while flexible and lightweight, are not designed for rugged use. They can be damaged more easily if exposed to heavy wear, extreme temperatures, or corrosive substances. If you’re using a cord in a setting where it might be dragged across rough surfaces or exposed to heavy loads, SVT cords simply won’t last as long.

Flexibility and Weight

While SJT cords are more rugged, they are also generally thicker and heavier. This can sometimes make them less convenient to maneuver in tight spaces or in applications where flexibility is key. However, newer models of SJT power cords are being manufactured with enhanced flexibility without compromising on strength.

SVT cords, being lighter and more flexible, are often preferred in situations where ease of use and portability are more important than extreme durability. For example, they’re commonly used in medical devices, small office equipment, and audio/video gear. But again, they’re not cut out for heavy-duty applications.

Insulation and Jacket Materials

The type of insulation and outer jacket also plays a role in determining the suitability of a power cord for specific environments. SJT power cords usually have thicker thermoplastic jackets that offer better protection against physical damage and chemical exposure. Some SJT cords are even designed to be water-resistant, adding another layer of safety in industrial or outdoor applications.

SVT cords, meanwhile, have thinner jackets that are adequate for light-duty use. They provide basic protection but are not suitable for environments where the cord might be exposed to sharp objects, heat sources, or corrosive materials.

Compliance and Safety Standards

Both SJT and SVT cords are generally UL-listed, meaning they meet specific safety standards set by Underwriters Laboratories. However, SJT power cords often come with additional certifications that make them acceptable for more specialized or regulated environments. For instance, some SJT cords are approved for use in hospitals, laboratories, or outdoor settings, depending on their construction.

SVT cords can also be UL-listed, but their intended use is usually restricted to less demanding applications. So if your industry is one that requires strict compliance with safety standards, SJT cords may offer more flexibility and assurance.

Cost Considerations

It’s no surprise that with greater durability and performance comes a higher price tag. SJT power cords tend to be more expensive than SVT cords, largely due to the higher-quality materials and more rugged construction. However, this upfront cost can often be justified by their longer lifespan and reduced risk of failure in critical settings.

SVT cords are more affordable and might be the right choice for budget-conscious applications where the power demand is low and the environment is controlled. But keep in mind, replacing damaged or worn-out cords frequently can become more expensive in the long run.

Where Each Cord Excels

Let’s take a look at where each type of cord really shines. SJT power cords are excellent for use with power tools, industrial machinery, generators, heavy-duty lighting, and even outdoor equipment like lawnmowers or electric grills. Their rugged build makes them dependable in high-stress environments.

SVT cords, by comparison, are more commonly found in consumer electronics, computer peripherals, lamps, and small appliances. They are not meant to be dragged across a factory floor or exposed to extreme conditions.

Longevity and Maintenance

One of the less discussed but equally important aspects is the maintenance and lifespan of power cords. SJT power cords generally require less frequent replacement, and when properly cared for, they can last for years without showing significant wear. Cleaning and inspecting them periodically for damage can further extend their life.

SVT cords, due to their lighter construction, may require more frequent inspections and replacements, especially if they are used in borderline environments. Fraying, splitting, or brittleness can occur sooner, making maintenance more of a recurring task.

So, Which One Is Better for Heavy-Duty Use?

After breaking down all the major factors—durability, voltage capacity, flexibility, insulation, safety standards, and longevity—it’s clear that SJT power cords are the superior choice for heavy-duty use. Their robust construction, higher ampacity ratings, and ability to perform well in tough environments make them a reliable option for industrial and outdoor applications.

SVT cords serve their purpose well in controlled, light-duty environments but fall short when exposed to the challenges of heavy-duty operations. If you’re outfitting a worksite, powering up industrial machinery, or simply want a long-lasting and safe solution, SJT is the way to go.

FAQs

Can I use an SVT cord for industrial equipment?

No, SVT cords are not designed for heavy-duty or industrial use. They are best for light-duty applications such as small appliances or electronics.

Are SJT power cords flexible enough for home use?

Yes, many modern SJT power cords are designed with enhanced flexibility, making them suitable even for home and light commercial use.

What does the ‘T’ in SJT and SVT stand for?

The ‘T’ stands for “Thermoplastic,” indicating the type of insulation material used in both cord types.

Which is more cost-effective in the long run—SJT or SVT?

Although SJT power cords have a higher upfront cost, their durability and longer lifespan make them more cost-effective over time in demanding environments.

Choosing the right power cord might seem like a small decision, but in reality, it can have significant implications for safety, performance, and cost-efficiency. Always consider the demands of your specific application and weigh them against the capabilities of the cord you’re planning to use. Check out High Tech Cords for a variety of solutions tailored to your needs. Contact them via email or by calling (614) 920-0853.

Leave a Comment